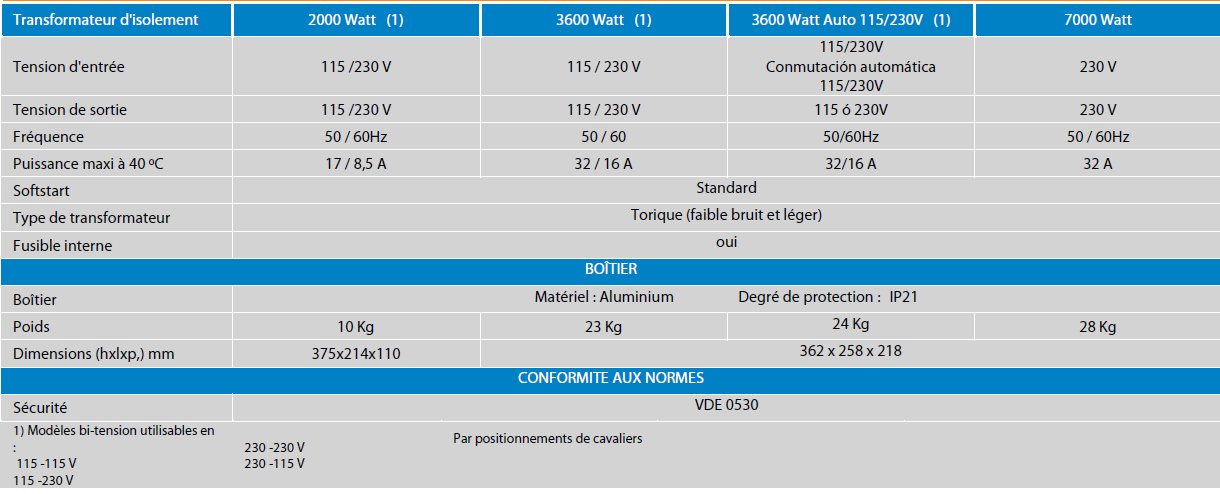

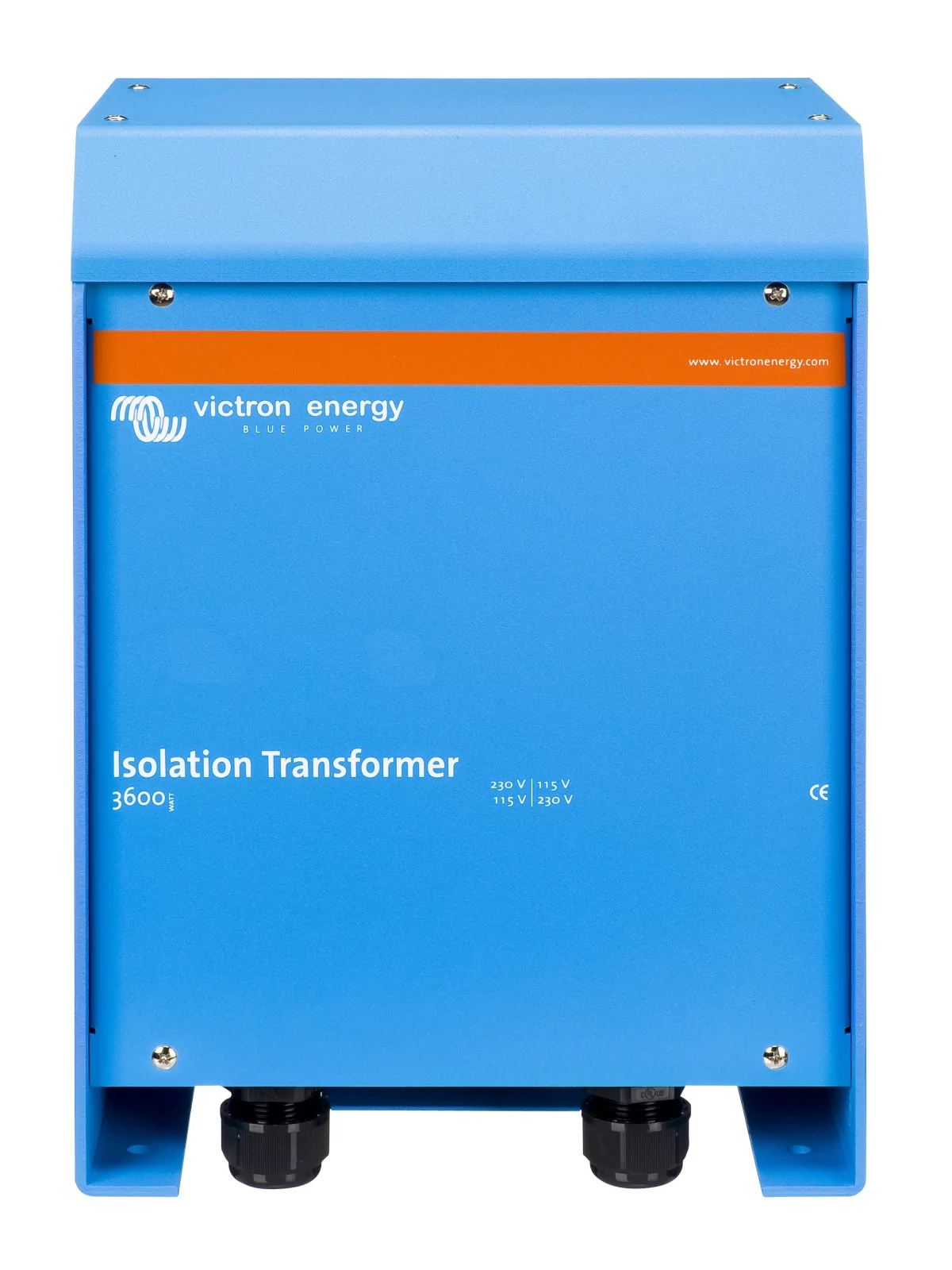

Isolation transformer Victron 2000, 3600, 3600 auto and 7000W

Indispensable for professional marine power systems. Prevents electrolytic corrosion and guarantees a safe electrical system. Discreet toroidal winding technology for high efficiency.

Please select your model in the options.

"Indispensable for professional marine energy systems".

It prevents electrolytic corrosion and, above all, ensures a safe electrical system. Discreet toroidal winding technology for high efficiency. A simple set of start-up circuits will ensure that the shore circuit breaker won't trip when plugged in.

Safety and prevention of electrolysis

Probably the most misunderstood component of a boat's electrical installation, the isolation transformer plays a very important role: electrical separation of the on-board network from the shore power supply. The isolation transformer is therefore an important safety element, which also helps prevent electrolytic corrosion.

Safety is a well-known feature of domestic installations, where earthing ensures that, in the event of a problem, a fuse or differential circuit breaker immediately cuts off the power supply. Such an earthing system is obviously not feasible on a boat, and only an isolation transformer can be used to reconstitute a protective "earth".

Electrolytic corrosion is a much-talked-about phenomenon on many boats. It is caused by the natural difference in potential between metals. When two of these metals are in a conductive liquid (seawater is a very good example) and a current flows in a closed circuit, the less noble metal will corrode to the benefit of the more noble one, giving up its ions.

In practice, the electrical circuit between the metals is closed as soon as the boat is connected to the shore power supply: a current begins to flow between the boat's metal and the shore ground, and the slow corrosion process begins.

The big misunderstanding is that this creeping danger only occurs on steel or aluminum boats.

In reality, as soon as the slightest metal part of a boat comes into contact with the water (as is always the case with the propeller and its shaft), the electrolytic corrosion process starts as soon as an electrical connection to the shore is used.

Electrolytic corrosion will attack the anodes, the propellers, the motor, and in the case of metal boats, the hull and its expensive paintwork.

It would therefore be preferable not to connect the boat to the quayside socket, but elementary safety rules do not allow this: in the event of a fault, very dangerous voltages could be present on metal parts, and the differential protection would be inoperative.

The best solution for powering a boat from the quay in complete safety and without risk of electrolytic corrosion is therefore to use an isolation transformer.

This type of transformer with separate windings transmits electricity without any direct contact with the shore power supply, and reconstitutes an insulated ground specific to the on-board network, to which all the boat's grounds (metal parts) are connected. The boat is thus perfectly protected and secure, with differential circuit breakers operating normally.

The complicated problems of electrolytic corrosion and its damaging effects are thus resolved simply and economically.

Softstart is a standard feature of Victron Energy's isolation transformers, clearing inrush currents on power-up and preventing any overloading of the shore power socket.